Increased surgical accuracy

The pre-determination of all incision and screw placement locations is ensured by this service.

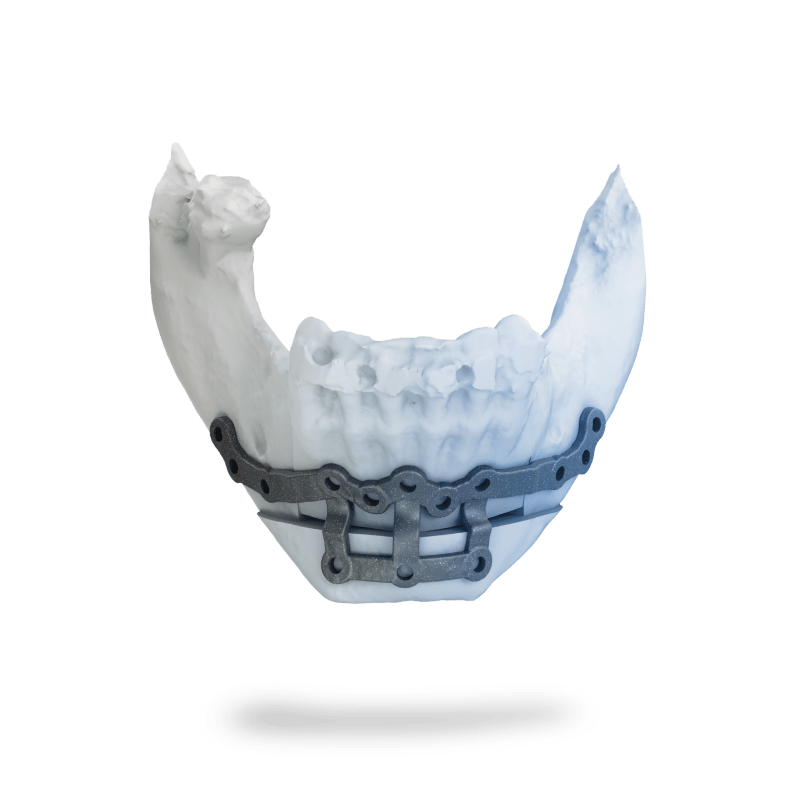

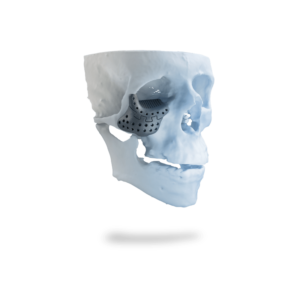

No need for bending plates

The design of these plates is based on the complete simulation of the osteotomy.

Reduced surgery duration

The design of custom plates helps the surgeon control and align bone segments more easily.

Elimination of splints in orthognathic surgery

Fixing the custom plate at pre-determined incision sites ensures the bone segments are placed correctly.